|

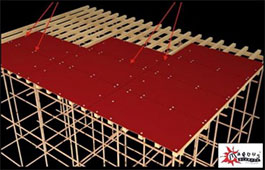

Magnus film faced shuttering plywood is manufactured with high density timber in ultra modern hot presses. Manufactured with CPGL technology, it offers extra strength and better bonding when compared to similar products in the market. The panels are most suitable for RCC construction sites.

Application: It is being used widely in the construction of bridges, flyovers, metro projects, ship building, water tanks, cooling towers, all high rise buildings etc., which need maximum strength and security. Sizes: 1840 x 1220 mm, 2440 x 1220 mm, 2745 x 1525 mm, 3050 x 1525 mm, 3200 x 1675 mm

Don’t

|

|

| TECHNICAL SPECIFICATIONS | |||||

| Dimension | BIS Requirement | Observation Values | |||

| 1. | Length |

|

2442mm | ||

| 2. | Width |

|

1222mm | ||

| 3. | Thickness | 12mm ± 5% | 11.90mm | ||

| 4. | Squareness | 2 mm/1000 mm | 0.95mm | ||

| 5. | Edge straightness | 2 mm/1000 mm | 0.50mm | ||

| Physical properties | |||||

| 6. | Density | 0.95 | 0.95 | ||

| 7. | Moisture contents | 5- 15% | 7.50% | ||

| 8. | Adhesion of plies (in dry state) | Some adherent fibre distributed more or less uniformly | Satisfactory | ||

| 9. | Adhesion of plies (in wet state) | ---do--- | Satisfactory | ||

| 10. | Glue shear strength (in dry state) | Avg. - 1350N Ind. - 1100N |

1520N 1190N |

||

| 11. | Glue shear strength (in wet state) | Avg. - 1000N Ind. - 800N |

1260N 900N |

||

| 12. | Tensile strength |

|

525kg./cm2 370kg./cm2 |

||

|

895kg./cm2 | ||||

| 13. | Static bending strength along the grain M.O.E. Across the grain M.O.E. Along the grain M.O.R. Across the grain M.O.R. |

Avg. - 7500N/mm2 Ind. - 6700N/mm2 Avg. - 4000N/mm2 Ind. - 3600N/mm2 Avg. - 50 Ind. - 45 Avg. - 30 Ind. - 27 |

8420N/mm2 6975N/mm2 4800N/mm2 4000N/mm2 68N/mm2 50N/mm2 47N/mm2 31N/mm2 |

||

| 14. | Retention of preservative (ACC) | 12 kg/m2 | 12.95 kg/gm2 | ||

| 15. | Mycologial test (a) Visual inspection (b) Glue shear strength (c) Adhesion of plies |

(a) Show no separation sign Avg. - 1000N Ind. - 800 N Adherent fibre distributed ore or less uniformly |

1260 N 910 Satisfactory |

||